Flexible, Portable Soft Cover Notebooks for Everyday Use

The Evolving Landscape of Professional Note-Taking Solutions

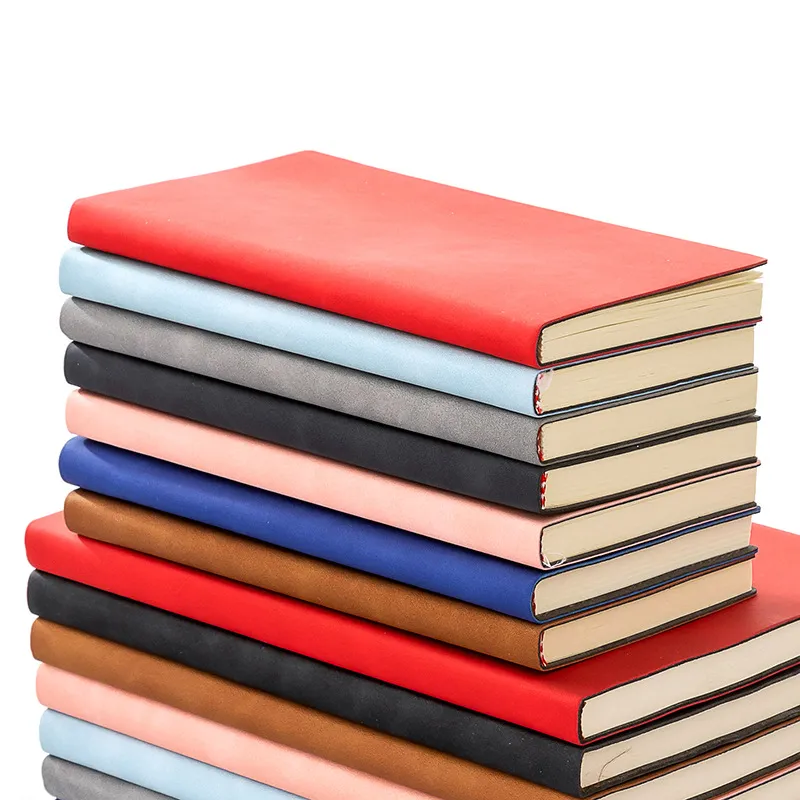

In today's dynamic business environment, the demand for adaptable and high-quality stationery remains constant. Among the myriad options, Soft Cover Notebooks have emerged as a preferred choice for their unparalleled versatility, portability, and aesthetic appeal. These notebooks cater to a diverse range of professional needs, from daily journaling and meeting notes to promotional giveaways and corporate branding initiatives. The industry is currently witnessing a significant trend towards sustainable materials and highly customizable designs, driven by increasing corporate social responsibility and the desire for unique brand representation. Manufacturers are continuously innovating to offer enhanced durability, superior paper quality, and diverse binding options, ensuring these notebooks meet the rigorous demands of modern enterprises while reflecting a commitment to environmental stewardship.

Market analysis indicates a steady growth in the demand for customized writing instruments, with a particular emphasis on products that offer both functional utility and branding opportunities. Businesses are increasingly recognizing the value of tangible brand touchpoints, and Soft Cover Notebooks serve as an excellent medium for consistent brand exposure. The integration of advanced printing technologies allows for intricate design elements, corporate logos, and custom messaging, transforming a simple notebook into a powerful marketing tool. This trend is further amplified by the shift towards agile work environments, where portable and lightweight note-taking solutions are essential for productivity and organization, reinforcing the enduring relevance and strategic importance of high-quality soft cover notebooks in the B2B sector.

Technical Specifications and Material Excellence

Understanding the technical parameters of Soft Cover Notebooks is crucial for procurement managers and marketing professionals to ensure optimal performance and brand alignment. Key specifications include paper weight (GSM - grams per square meter), which dictates the paper's thickness and opacity, impacting bleed-through and overall writing experience. Common options range from 80 GSM for standard use to 120 GSM for premium applications, offering superior ink resistance. Cover material choices are extensive, encompassing various textures of cardstock, flexible synthetic leathers, or recycled board, each providing distinct tactile qualities and durability. The choice of cover material significantly influences the notebook's perceived value and longevity, crucial for products intended for prolonged use or high-impact promotional campaigns.

Figure 1: High-capacity production line for Soft Cover Notebooks, ensuring quality and efficiency.

Binding methods are another critical technical aspect, influencing both durability and user experience. Perfect binding, where pages are glued at the spine, offers a clean, professional finish, ideal for executive notebooks. Saddle-stitching, using staples along the fold, is cost-effective for thinner notebooks, while spiral or wire-o binding allows for 360-degree page rotation, enhancing usability. These technical details directly impact the suitability of the Soft Cover Notebooks for specific application scenarios. For example, a marketing agency might prioritize a thicker cover and perfect binding for a premium client gift, while a school district might opt for durable spiral binding and a high GSM paper for student use. Adherence to international standards, such as ISO 9001 for quality management systems in manufacturing, ensures consistent product quality and reliability.

Typical Soft Cover Notebook Specifications

| Parameter | Description | Common Range/Value |

|---|---|---|

| Dimensions | Standard sizes for portability and desk use. | A5 (5.8 x 8.3 in), A4 (8.3 x 11.7 in), B5 (6.9 x 9.8 in) |

| Paper Weight (GSM) | Grams Per Square Meter, indicating paper thickness and opacity. | 80 GSM - 120 GSM (internal pages) |

| Number of Pages | Total pages, including front and back (leaves x 2). | 96 - 200 pages (48 - 100 leaves) |

| Binding Type | Method used to join the pages and cover. | Perfect Bound, Saddle-Stitched, Spiral Bound, Section Sewn |

| Cover Material | Material used for the flexible outer cover. | Cardstock (250-350 GSM), Flexible PU Leather, Recycled Kraft Paper |

| Paper Ruling | Pre-printed lines or patterns on pages. | Lined, Dotted, Grid, Blank, Custom |

| Finishing Options | Post-printing treatments for cover and pages. | Matte/Gloss Lamination, Spot UV, Embossing, Debossing, Foil Stamping |

| Certifications | Relevant industry and environmental standards. | FSC (Forest Stewardship Council), ISO 9001 (Quality) |

The Craftsmanship: Manufacturing Process of Soft Cover Notebooks

The production of high-quality Soft Cover Notebooks is a refined process that combines precision engineering with artisanal attention to detail. It begins with the meticulous selection of raw materials. For internal pages, paper stock is chosen based on specified GSM, brightness, and eco-certifications like FSC, ensuring responsible sourcing. Cover materials range from robust cardstock to advanced synthetic blends, selected for durability, printability, and tactile properties. Inks used are often vegetable-based for environmental reasons, ensuring vibrant color reproduction while adhering to safety standards. This foundational step is critical in determining the final product's quality, feel, and environmental footprint, setting the stage for subsequent manufacturing stages with a focus on sustainable and high-performance components.

Figure 2: Precision paper processing for Soft Cover Notebooks, ensuring consistent sheet quality.

Following material preparation, the printing phase employs advanced digital or offset lithography techniques. Digital printing is ideal for shorter runs and variable data, offering quick turnaround times and cost-effectiveness for personalized Soft Cover Notebooks. Offset printing, preferred for large volumes, delivers superior color consistency and sharp image resolution, leveraging precise ink-to-paper transfer. Post-printing, the sheets undergo precise cutting and folding to create the internal blocks and covers. This is a critical step for perfect alignment and squareness. The binding process then integrates these components. Perfect binding involves roughing the spine and applying a strong, flexible adhesive, creating a flat, professional spine. Saddle-stitching is used for thinner notebooks, while spiral or wire-o binding uses pre-punched holes for maximum flexibility.

The final stages involve finishing and quality control. Finishing options include matte or gloss lamination for cover protection and enhanced aesthetics, spot UV for tactile and visual contrast, and specialized embellishments like embossing, debossing, or foil stamping to add premium tactile and metallic effects. Each notebook then undergoes rigorous inspection against strict quality standards, which include checks for print registration, color accuracy, binding integrity, and overall structural soundness. This comprehensive quality assurance process, often guided by ISO 9001 principles, ensures that every batch of Soft Cover Notebooks meets the specified technical parameters and aesthetic expectations, guaranteeing a product of exceptional quality and durability for the intended application, whether in high-traffic corporate environments or as a lasting promotional item.

Technical Advantages and Versatile Applications

The inherent design and material science behind Soft Cover Notebooks confer several distinct advantages that make them highly adaptable for diverse B2B applications. Their primary technical advantage lies in their superior portability and flexibility. Unlike their hard-cover counterparts, soft cover notebooks can easily flex and adapt to various carrying conditions, making them ideal for professionals on the go, field technicians, or sales teams attending multiple meetings. This flexibility also reduces the likelihood of damage from bending or impact, contributing to a longer usable lifespan under typical daily handling. Furthermore, their lighter weight contributes to reduced shipping costs for bulk orders, providing a logistical and economic benefit for companies distributing them widely.

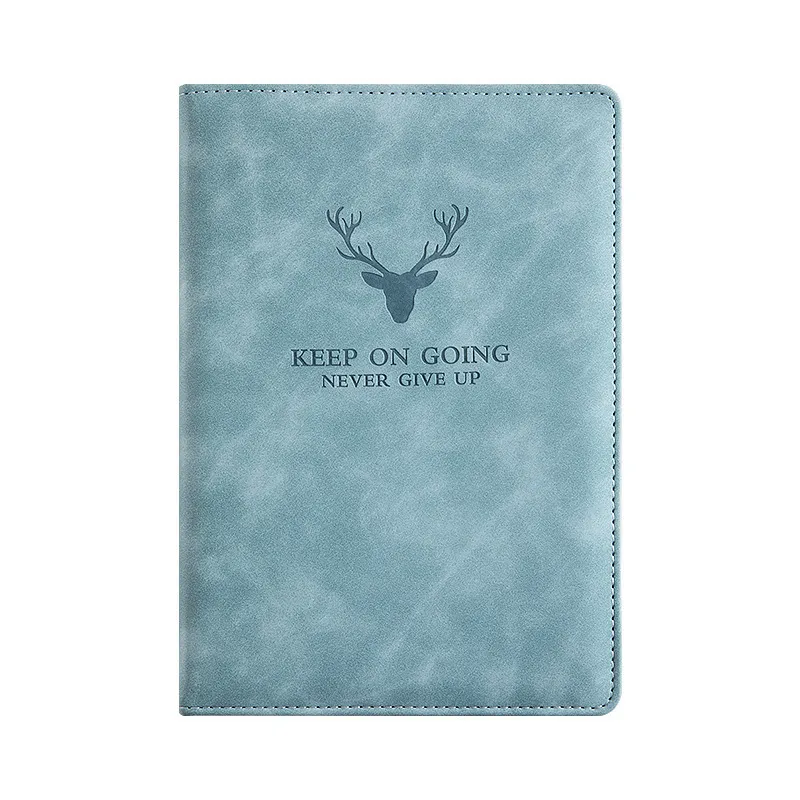

Figure 3: Exploring diverse design options for custom Soft Cover Notebooks.

From an application perspective, Soft Cover Notebooks excel in scenarios requiring cost-effectiveness without compromising on quality or branding impact. In the education sector, they are widely adopted for student supplies, offering durable yet affordable note-taking solutions. Corporate environments leverage them extensively for internal meetings, training sessions, and employee onboarding kits, providing a professional and functional tool. For marketing and promotional activities, they serve as highly effective branded merchandise. Their customizable covers offer ample space for vibrant logos, taglines, and brand imagery, transforming them into mobile advertisements that reinforce brand identity with every use. Their cost-efficiency in bulk production makes them particularly attractive for large-scale distribution at conferences, trade shows, or as part of direct mail campaigns.

Customization Solutions and Brand Integration Mastery

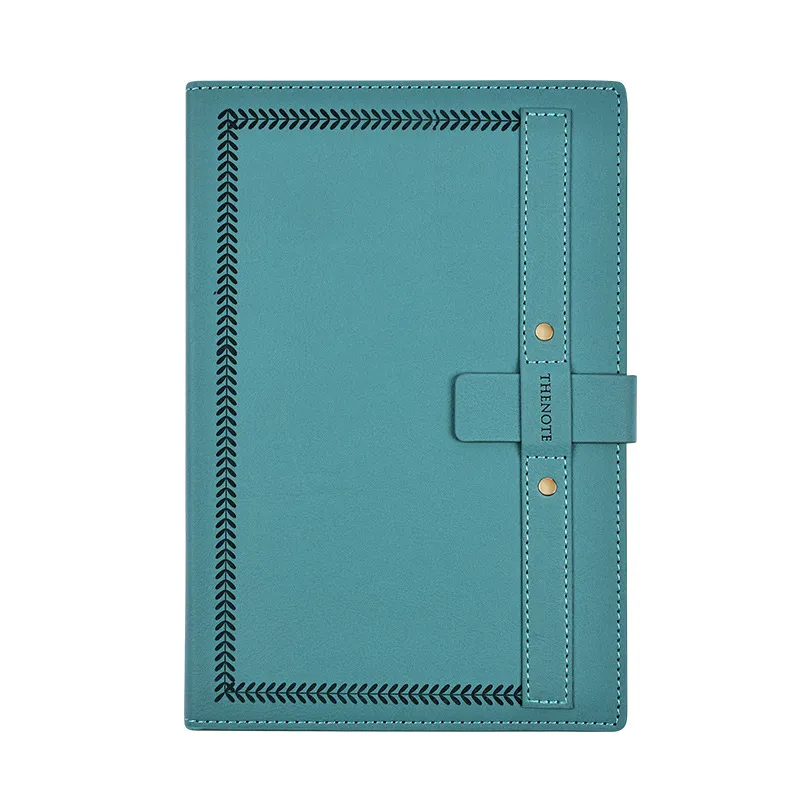

The true power of Soft Cover Notebooks in a B2B context lies in their extensive customization capabilities, allowing businesses to transform a standard item into a bespoke branding asset. Customization extends beyond merely printing a logo; it encompasses a comprehensive design strategy. Clients can specify unique cover designs, choosing from a wide palette of colors, textures, and finishes such as matte or gloss lamination, soft-touch coatings, or even debossing for a subtle, elegant brand mark. The internal pages can also be customized with company-specific templates, branded watermarks, or even relevant corporate information such as mission statements or contact details, ensuring consistency across all branded materials.

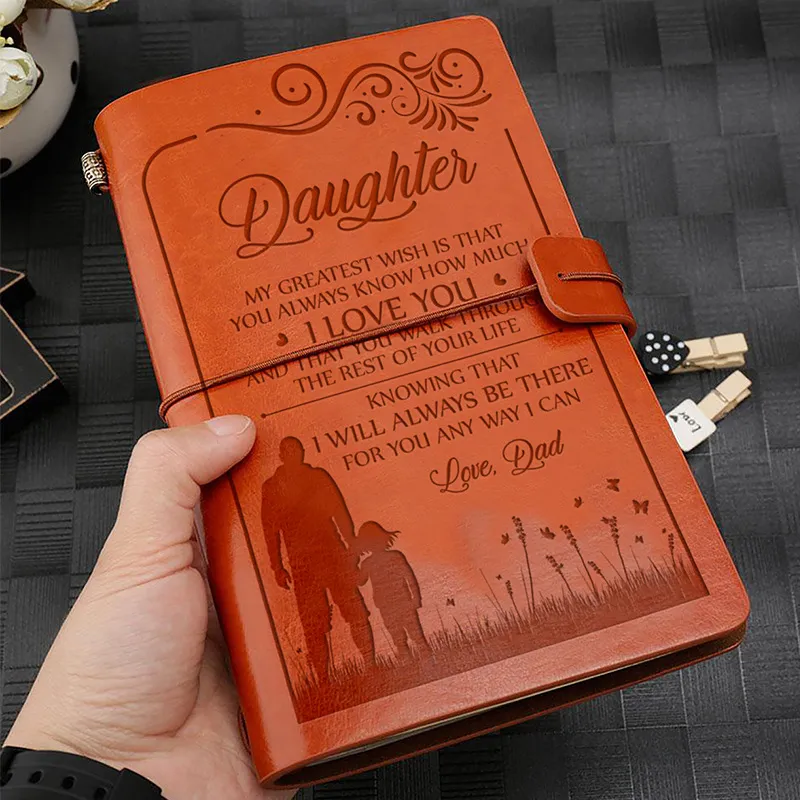

Figure 4: Exemplary brand integration on customized Soft Cover Notebooks.

Advanced printing technologies, including full-color digital printing and intricate foil stamping, enable high-fidelity reproduction of complex graphics and corporate branding. This allows companies to align the visual identity of their Soft Cover Notebooks perfectly with their overall marketing collateral. For instance, a tech firm might opt for a minimalist design with a metallic foil logo, conveying innovation and sleekness, while a non-profit might choose a recycled paper cover with a nature-inspired design to reflect their values. The ability to tailor every element, from page count and ruling to binding style and additional features like elastic closures or pen loops, provides unparalleled flexibility. This level of granular control ensures that the final product not only serves its functional purpose but also acts as a powerful, consistent extension of the brand's identity and message, enhancing brand recall and reinforcing corporate image.

Application Cases and Client Success Stories

The practical application of custom Soft Cover Notebooks spans a wide array of industries, demonstrating their strategic value in real-world scenarios. A prominent software development firm, for instance, implemented personalized notebooks as part of their new employee welcome kits. Each notebook featured the company's vibrant logo and a custom quote on the cover, along with internal pages incorporating their brand colors and a 'team values' section. This initiative not only provided practical tools for new hires but also fostered a strong sense of belonging and brand identity from day one, significantly improving the onboarding experience as reported in internal surveys and anecdotal feedback from employees who appreciated the thoughtful, branded utility.

Figure 5: Soft Cover Notebooks as essential tools in corporate environments.

Another notable case involves a global conference organizer who commissioned a large volume of custom Soft Cover Notebooks as part of attendee registration packages. These notebooks were designed to match the conference's theme, featuring event schedules and sponsor logos on dedicated internal pages. Post-event feedback indicated that attendees highly valued the practical utility of the notebooks, using them throughout the event and retaining them afterward as a souvenir. This extended the event's brand reach and provided ongoing exposure for sponsors, proving a tangible return on investment. Furthermore, a leading university utilized customized soft cover notebooks for their alumni outreach programs, embedding motivational messages and university crests. These served as elegant tokens of appreciation, strengthening alumni ties and encouraging continued engagement, showcasing the enduring appeal and strategic utility of these versatile promotional items across diverse organizational objectives.

Selecting Your Supplier: Key Considerations for Quality and Reliability

Choosing the right manufacturing partner for your Soft Cover Notebooks is paramount to ensuring product quality, timely delivery, and effective brand representation. Key factors to evaluate include the manufacturer's demonstrated expertise in various printing and binding techniques, their capacity for customization, and their adherence to stringent quality control protocols such as ISO 9001. A reputable supplier will offer a broad range of material options, including sustainably sourced papers (FSC certified) and eco-friendly cover stocks, showcasing a commitment to environmental responsibility. Furthermore, assess their sample production capabilities and their willingness to provide mock-ups, which are crucial for visualizing the final product and making informed design decisions before full production commences.

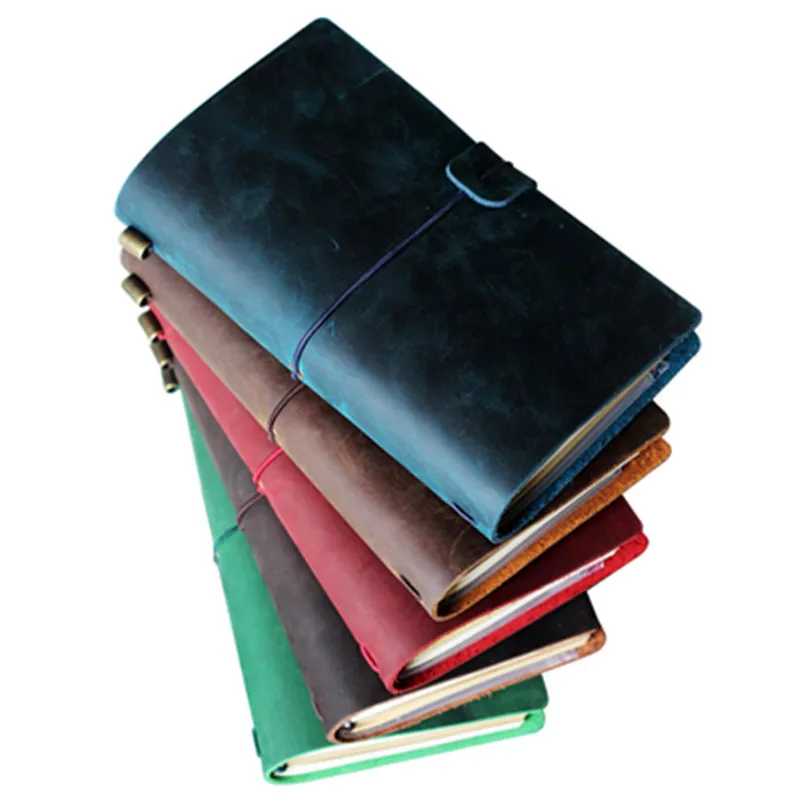

Figure 6: A range of customization options available for Soft Cover Notebooks.

Beyond product specifications, evaluate the manufacturer's operational efficiency, lead times, and logistical support. A streamlined process from design consultation to final delivery is indicative of a mature and reliable partner. Look for transparent communication channels and a dedicated account management team that can provide regular updates and address any concerns promptly. Proven service longevity and positive client testimonials, especially from enterprises with similar procurement needs, serve as strong indicators of a manufacturer's credibility and trustworthiness. Partnering with an experienced supplier ensures that your investment in custom Soft Cover Notebooks translates into a high-quality, impactful branding solution that perfectly aligns with your organizational objectives and enhances your market presence.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom Soft Cover Notebooks?

A1: Lead times vary based on order volume, customization complexity, and current production schedules. Generally, for bespoke designs and large quantities, production can range from 15 to 30 business days after final artwork approval. Expedited services may be available upon request, subject to capacity and additional charges.

Q2: What file formats are required for custom artwork?

A2: We typically require high-resolution vector files for optimal print quality, such as AI, EPS, or PDF. All fonts should be outlined, and images embedded. Our design team can provide detailed artwork specifications and templates to ensure a smooth submission process, ensuring your brand's visuals are reproduced with precision on your Soft Cover Notebooks.

Q3: What are the minimum order quantities (MOQ) for customized Soft Cover Notebooks?

A3: MOQs for customized Soft Cover Notebooks depend on the specific product configuration and level of customization. While some standard options may have lower MOQs, more complex designs or specialized materials might require higher minimums to ensure cost-efficiency in production. Please consult our sales team for detailed MOQ information relevant to your specific project.

Q4: Do you offer samples before a large production run?

A4: Yes, we highly recommend and can provide pre-production samples or digital mock-ups for review. This allows clients to assess the design, material quality, and overall finish before proceeding with the full order, ensuring complete satisfaction with the final Soft Cover Notebooks.

Commitment to Quality, Delivery, and Customer Support

Our unwavering commitment to excellence underpins every stage of the manufacturing process for Soft Cover Notebooks, from initial material sourcing to final dispatch. We adhere to rigorous quality control protocols, including multi-stage inspections, to ensure that each notebook meets precise specifications for paper quality, print fidelity, and binding integrity. This dedication to quality is backed by industry certifications and a long-standing reputation for reliability. Our standardized production processes, coupled with advanced machinery, enable us to maintain consistent product quality across all order sizes, from small custom runs to large-scale bulk productions for global distribution.

Understanding the critical nature of timely delivery in B2B operations, we employ optimized logistics and transparent communication channels. Clients receive regular updates on their order status, from production milestones to shipping notifications. Our robust supply chain management ensures efficient procurement and streamlined manufacturing, allowing us to meet agreed-upon delivery schedules consistently. Furthermore, our dedicated customer support team is readily available to provide expert guidance throughout the entire process, addressing technical queries, facilitating design revisions, and offering post-delivery assistance. This holistic approach guarantees not only superior Soft Cover Notebooks but also a seamless and supportive partnership, reinforcing our commitment to client satisfaction and long-term collaboration.

References

- Smith, J. R. "Innovations in Sustainable Paper Production for Commercial Applications." Journal of Sustainable Manufacturing, Vol. 15, No. 3, 2022, pp. 210-225.

- Marketing Institute Global. "The Tangible Impact: Measuring ROI of Promotional Products in B2B Branding." Marketing Research Quarterly, Vol. 28, No. 1, 2023, pp. 45-62.

- International Organization for Standardization. "ISO 9001:2015 Quality Management Systems – Requirements." ISO, 2015.

- Print & Packaging Federation. "Advanced Binding Technologies and Their Applications in Modern Stationery Production." Technical Printing Journal, Vol. 10, No. 2, 2021, pp. 88-105.

- Forest Stewardship Council. "FSC Principles and Criteria for Forest Stewardship (V5-2)." FSC International, 2017.